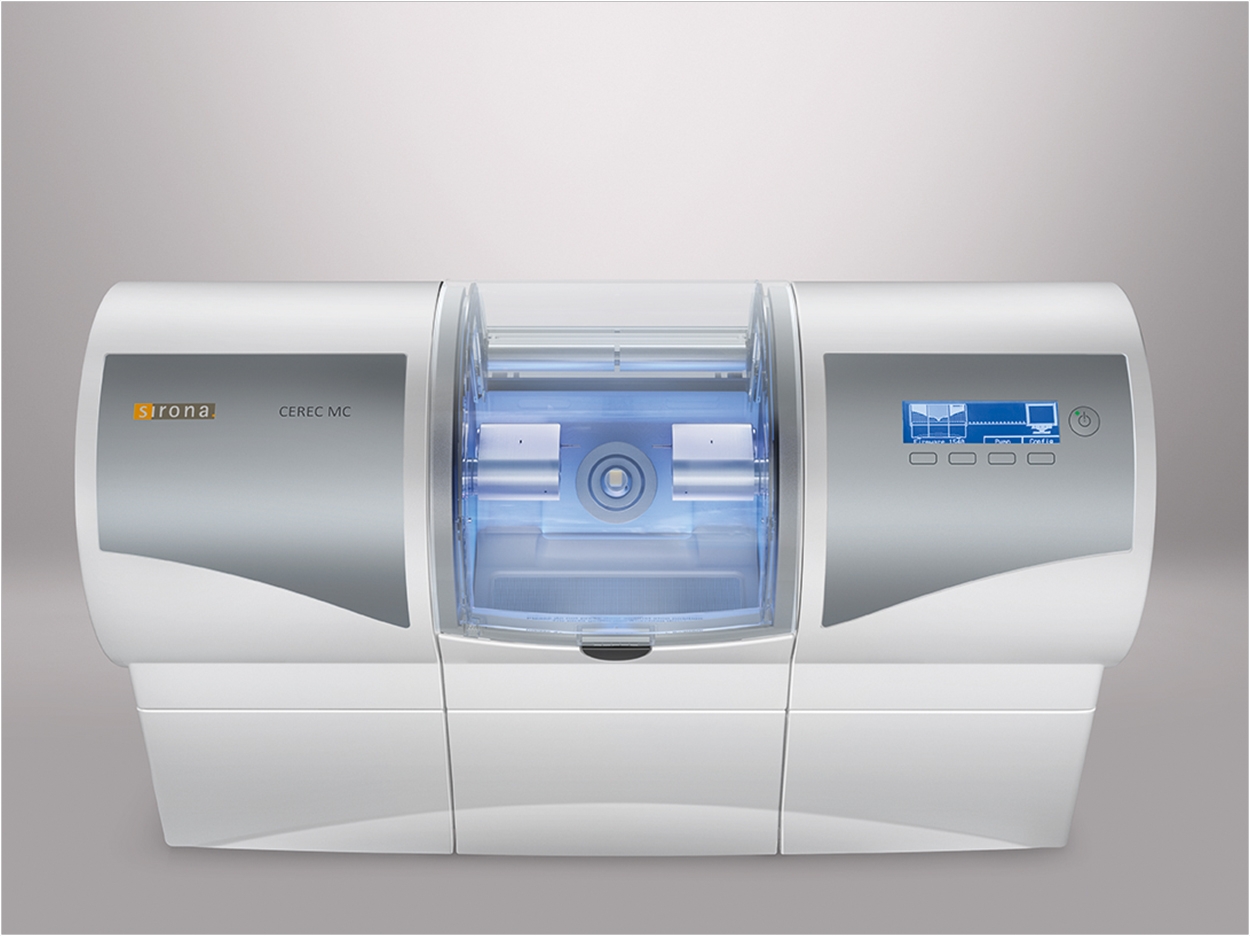

Dentsply Sirona’s CEREC MC milling unit is now available again in the United States as part of the CEREC product portfolio. The entry-level milling solution is designed for practitioners who are interested in single-visit chairside inlays, onlays, and single-unit veneers and crowns. It also can wet grind and dry mill, so dentists can use a vast array of chairside materials to produce single-unit restorations in one office visit.

The milling unit is part of the plug-and-play CEREC workflow. Used in conjunction with the CEREC Omnicam, the CEREC MC:

- Provides fully anatomical single-unit restorations;

- Supports block sizes up to 20 mm;

- Can produce ceramics, glass ceramics, lithium disilicate blocks, and more;

- Mills zirconium oxide and polymers;

- Is dry-mill ready;

- Offers an entry option into digital dentistry and single-visit restorations.

“We used to say CAD/CAM was the future of dentistry, and as we enter 2018, it’s become clear that it is now the present,” said Lou Vodopivec, Dentsply Sirona director of marketing, clinical CAD/CAM. “CEREC MC offers a cost-competitive option to incorporate efficient workflows, improving productivity and patient satisfaction. We are excited to reintroduce this high-quality product with a flexible upgrade path that grows with the needs of the practice.”

Providing an avenue for future development, Dentsply Sirona is offering an upgrade path for anyone who purchases a CEREC MC milling unit between now and June 1, 2018. All MC units purchased during this timeframe are eligible for an upgrade to the CEREC MC XL Practice Lab Milling Unit within 24 months of ownership.

Related Articles

CEREC Data Now Exportable in STL Format

Hybrid Blocks/Discs Suit CEREC Restorations

Straumann and Sirona Partner on Prosthetics