Full-Contour Zirconia

The use of full-contour zirconia has gained large acceptance and is used in a wide range of applications in dental treatment today. The rapid transition to zirconia monolithic restorations was accelerated by the clinical success of monolithic zirconia posterior ceramic restorations, accurate milling, and rising metal costs.

Most zirconia used in dentistry is mined from Australia and refined in China by large industrial ceramic manufacturers. Intermediate material of the refined product is mainly exported to Japan and made commercially available as various different grain powders with different physical properties. These will be used to make zirconia pucks or discs for dental laboratory use.

Zirconia Structure and Types

All zirconia is not the same; clinicians must be aware of the properties and differences between zirconia materials, which will affect the success or failure of their final restorations. Zirconia has a crystalline structure and is stabilized with various materials, such as Yittria. The conventional type (eg, KATANA HT [Kuraray Noritake Dental]) comprises a more tetragonal crystal phase and usually has a flexural strength of 1,000 to 1,200 MPa. The material is more opaque and limited to use in molars due to aesthetics. A few years ago, many dental manufacturers introduced zirconia with a higher translucency (eg, KATANA STML, KATANA UTML [Kuraray Noritake Dental]) by incorporating a more cubic crystalline phase and adjusting other parameters of the zirconia. These materials usually have a lower strength than the conventional type but higher flexural strength than lithium disilicate materials.

|

| Figure 2. The KATANA Zirconia Block can be sintered in 30 minutes. |

|

| Figure 3. The CEREC (Dentsply Sirona) digital work flow. |

|

| Figure 4. Crowns milled with the KATANA Zirconia Block. (Image courtesy of Dr. Daniel Vasquez.) |

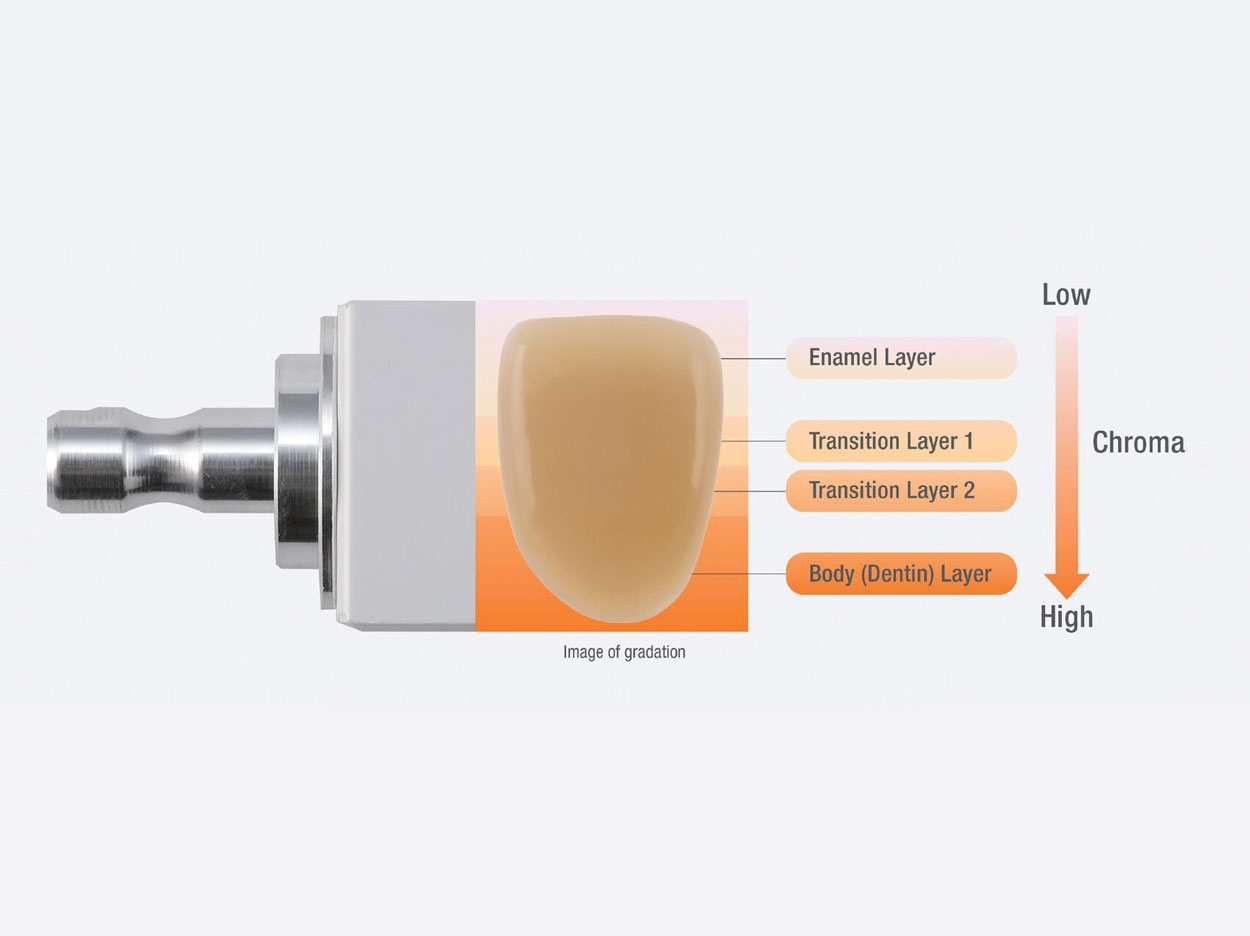

The KATANA Zirconia Block (Kuraray Noritake Dental) comprises 4 layers of zirconia in blended shades (Figure 1). This product allows the chairside fabrication of natural tooth-colored restorations, eliminating the time-consuming and difficult challenge associated with color matching a restoration.

Firing/Sintering of Zirconia

Until recently, aesthetic zirconia was not available as a chairside material due to its long firing cycle. Kuraray Noritake Dental introduced a new zirconia block that can be sintered in 30 minutes with the CEREC Speedfire sintering oven (Dentsply Sirona) (Figure 2).

Digital Flow With CEREC

CEREC users will be able to mill zirconia in 15 minutes and sinter it in 30 minutes (Figure 3), which will be a great option for using zirconia in one-day dentistry. Sintered crowns can be polished or glazed before insertion (Figure 4). Kuraray Noritake Dental pioneered its technology to make better aesthetics through high translucency. The material also has a higher strength than lithium disilicate, which helps to deliver a restoration that is not only aesthetic but also durable. Being able to enjoy aesthetics with the strength required for a restoration will be a tremendous breakthrough in zirconia as well as for CEREC users.

For more information, call Kuraray America at (800) 879-1676 or visit kuraraydental.com.