Incorporating 3D printing into the office workflow may seem like a daunting process, but the numerous benefits to the office and the patient make it worth the effort. We have a large, 4-doctor practice in Stratford, Conn, and our focus is on creating the best experience for the patient while finding the balance between the art, science, and business of dentistry. Providing same-day service as often as possible is of great importance to us; we accommodate emergencies the same day and often take patients from hygiene to provide same-day treatment. Patients appreciate how we value their time, and reducing the number of visits to the office is a huge practice builder.

Since the COVID-19 pandemic began, turnaround and shipping times for many laboratories have increased. Relying on dental laboratories means scheduling patients further out and occasionally having to reschedule when the appliance is not back in time—an inconvenience for both the practice and the patient. Three-dimensional printing has eliminated the time wasted in shipping and has given us control over when a case is ready to be delivered. For this reason, the ability to 3D print is essential to our office. If a patient loses a retainer or nightguard, we are able to fabricate a new one the same day and reduce the risk of orthodontic relapse or patient symptoms returning.

INTRODUCING 3D TO YOUR PRACTICE

The biggest challenge in introducing 3D printing to your practice is learning the digital workflow. However, once the team learns the software and the process for converting the STL file into a printable file, the rest of the process is straightforward.

In our office, the software training was very comprehensive, and our team was able to quickly learn and begin 3D printing the same day.

Several components are required to 3D print dental workpieces in the office: an intraoral scanner, appliance design software, integration software for the printer, a wash unit, and a curing unit. When choosing the right 3D printing solution our office, I quickly learned that it is important to fully understand the process and workflow that needed to be implemented. After understanding this process, we chose to begin our printing journey with DMG’s Digital 3D printing solution.

We did this for several reasons, which I will cover below. Overall, we found that DMG integrates a complete workflow system with cloud-based software. Radio-frequency identification (RFID) technology, and a validated process to create quality print results, is incorporated into an efficient, compact, easy, and user-friendly design.

UNDERSTANDING THE PROCESS

1. The process begins with an intraoral scan to generate an STL file of the patient’s oral environment. Getting a high-resolution, quality scan is important. There are many great scanners on the market. For our office, we incorporated the iTero scanner (Align Technology) and Medit i700 scanner.

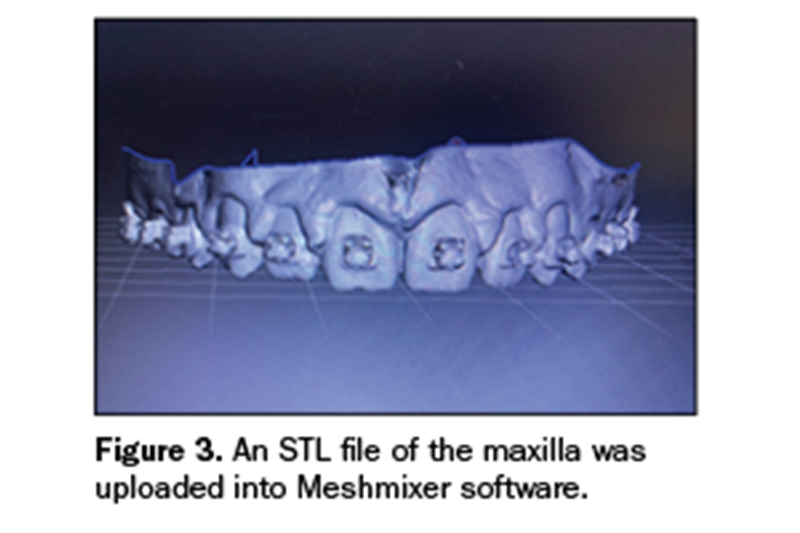

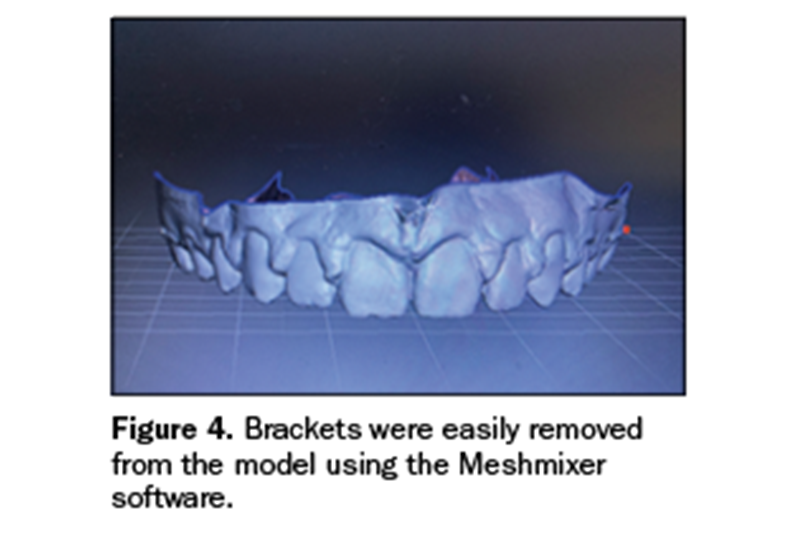

2. Next is the design of the workpieces. For most 3D printers to custom design workpieces such as sleep appliances, occlusal guards, or aligners, third-party software is used to create the design before sending it to the printer. Software such as Meshmixer or Blue Sky Bio may be used for design. We are currently using Blue Sky Bio to create each step in the clear aligner treatment.

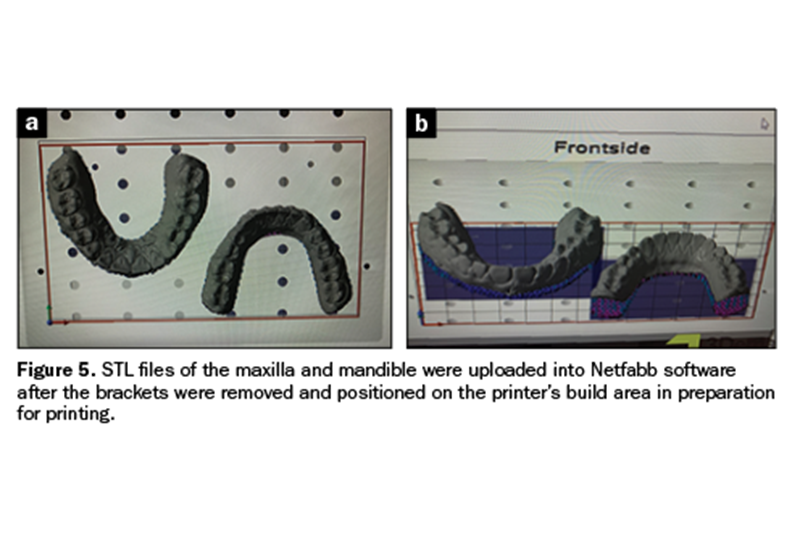

3. The designed STL files are then imported to a nesting and slicing software, Netfabb, where the workpieces are positioned on the printer’s build area in preparation for printing.

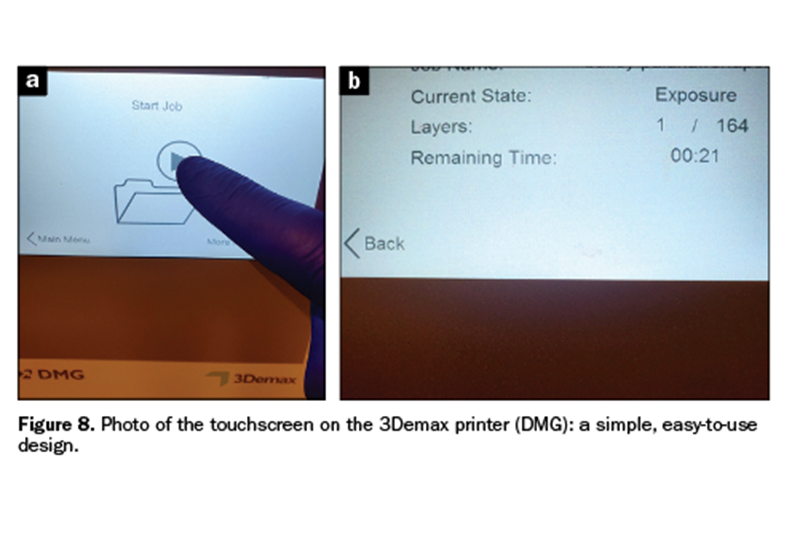

4. The 3D printer is then used to print the workpieces. We produce a high number of models for aligner orthodontic treatment. With 3Demax (DMG), the build area is a generous size, allowing multiple models to be printed simultaneously. Tags may be added to these models utilizing Netfabb software within the printer to identify the patient. The patented Force Feedback technology accelerates the printing process by up to 50% and minimizes the risk of misprints.

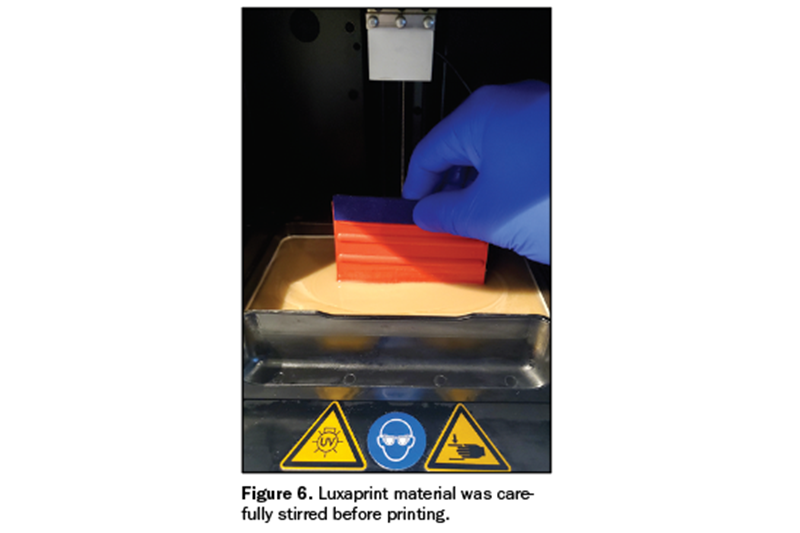

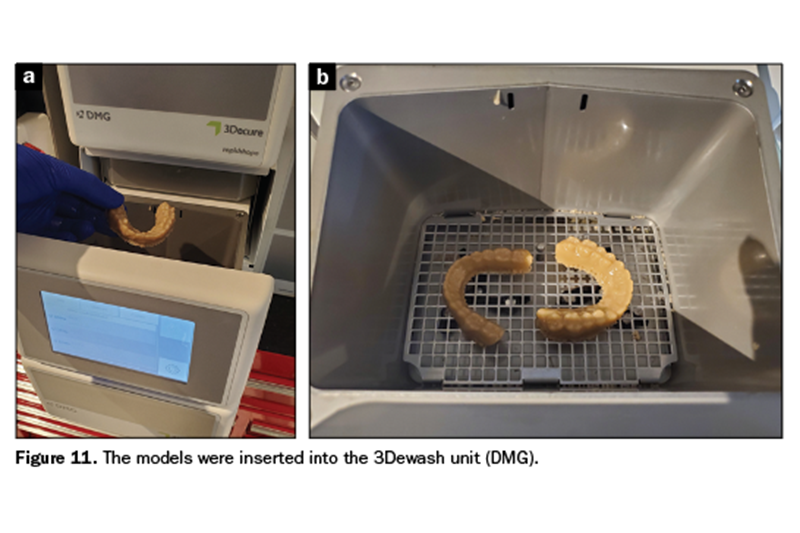

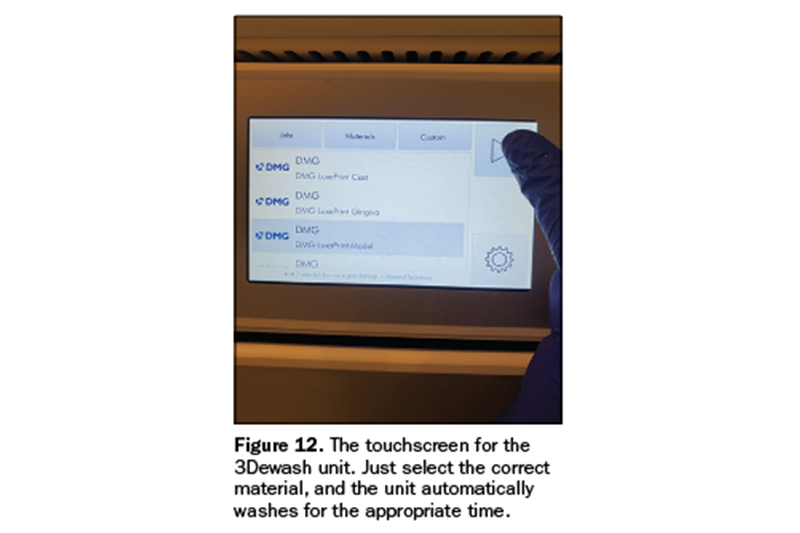

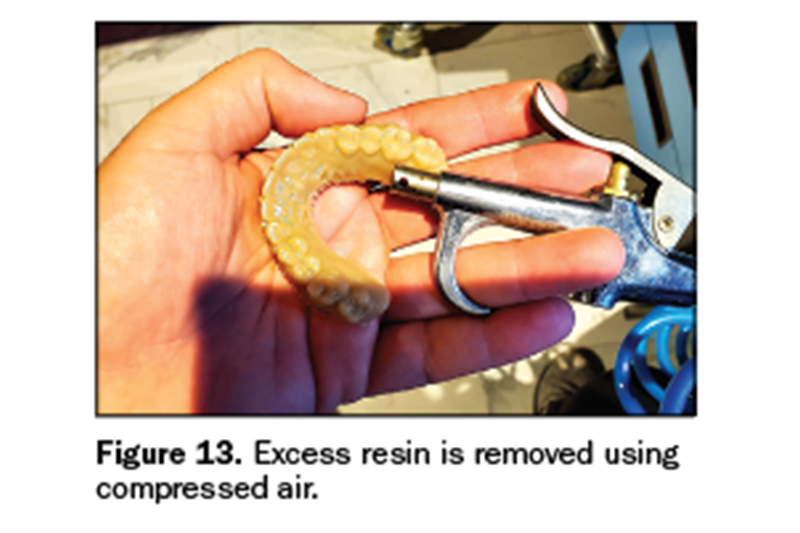

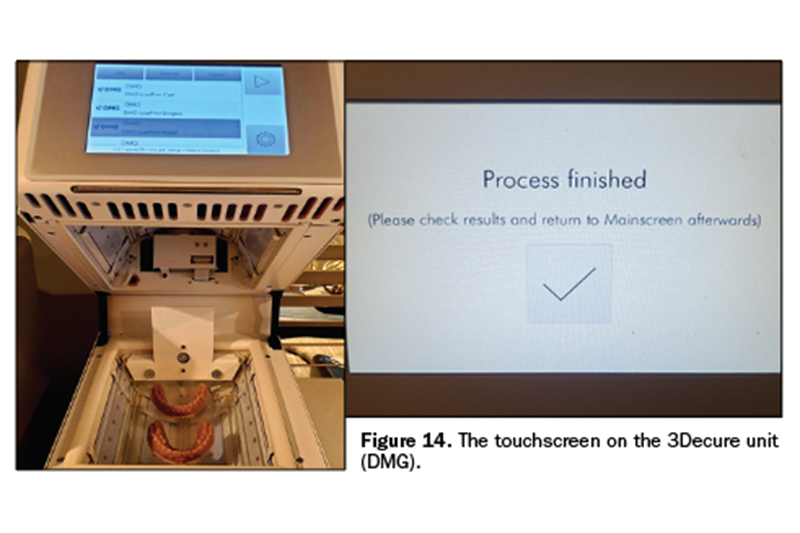

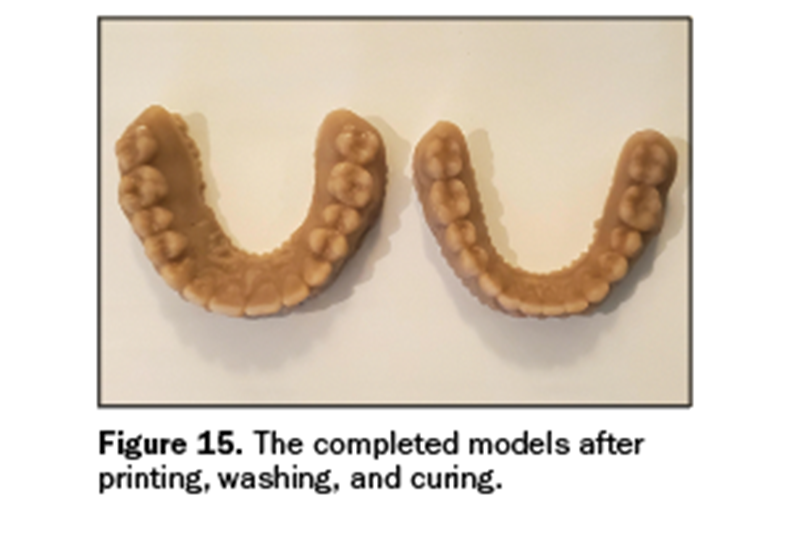

5. After printing, the pieces go through the additional processing steps of washing off residual resin and curing to the lock the mechanical properties. Many printing systems do not provide solutions for the final fabrication processes of the workpiece, instead giving only general instructions for using your choice of wash and cure systems. DMG has a validated, easy workflow for printing, washing, and curing, which ensures a quality printed workpiece every time. The appropriate material is chosen for the printed piece and loaded into the printing tray. DMG’s Luxaprint materials have a unique RFID, which is communicated to the printer using an RFID sensor. The display then shows the amount of time required for the build and the progress while communicating the correct wash and cure time for each process, validating the final print piece.

Although there are many choices, we chose a DMG printer that is evolving via software integration, which is one of our requirements. Later this year, DMG will launch cloud-based software called DentaMile connect that takes the above process and simplifies it further. We are in the process of testing this software, and, currently, a splint or nightguard can be designed and positioned using this one software platform. DMG is continuing to improve this software for ease of printing all applications with a comprehensive line of resins.

The number of applications for 3D printing will continue to increase throughout the year. Coming soon, Luxaprint Crown will allow the printing of semi-permanent crowns and bridges, and Luxaprint Orthoflex will be used for the printing of flexible dental splints, such as sports guards. DMG DentaMile connect will also offer easy steps to incorporate the correct amount of undercut on the appliance, the vertical opening, and the occlusion for a precisely planned and accurately fitting appliance, resulting in fewer chairside adjustments.

Once the team members are familiar with the software, this process is completed in just a couple of minutes.

BENEFITS TO PATIENT AND PRACTICE

The benefits of in-office 3D printing are numerous, including reducing laboratory costs and improving the patient experience. Eliminating the laboratory turnaround time and providing your patients with same-day service is a benefit for both the patient and the dental office. The ability to 3D print workpieces can reduce the need to reschedule patients because the appliance wasn’t back in time due to shipping or laboratory delays.

Taking an intraoral scan, rather than a traditional impression, is much more comfortable for the patient and allows the patient to visualize his or her oral environment and better understand and accept the treatment required. The digital file is much more convenient to store, and 3D printed models can be saved and used numerous times without breaking due to their increased strength. The large build area on the 3Demax allows many workpieces to be printed simultaneously and at a fast pace with the Force Feedback technology.

The simple, user-friendly design allows the staff to learn the process quickly and incorporate it into the office workflow.

Reducing office overhead is also a major benefit. The ability to design and print your own clear aligners can cut down on outside laboratory costs.

CASE REPORT

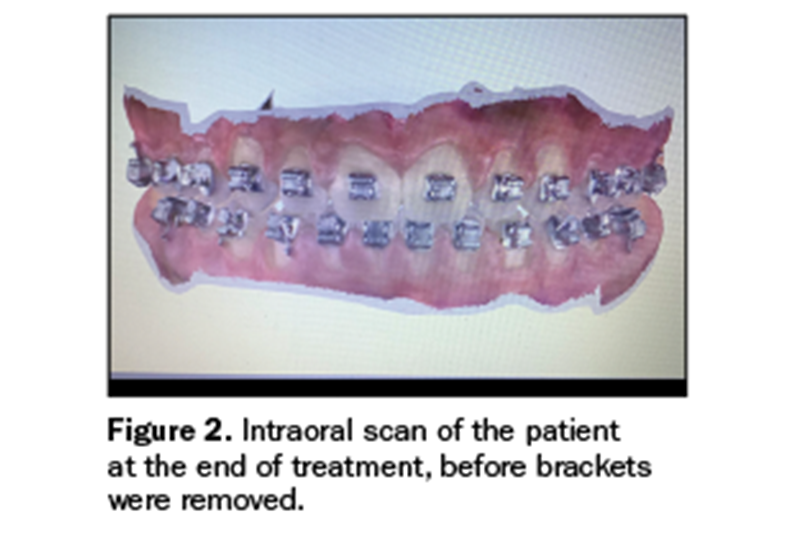

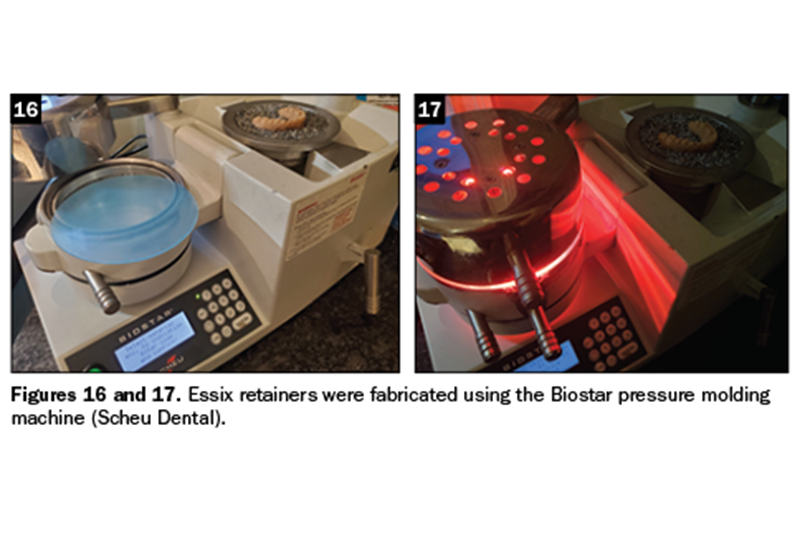

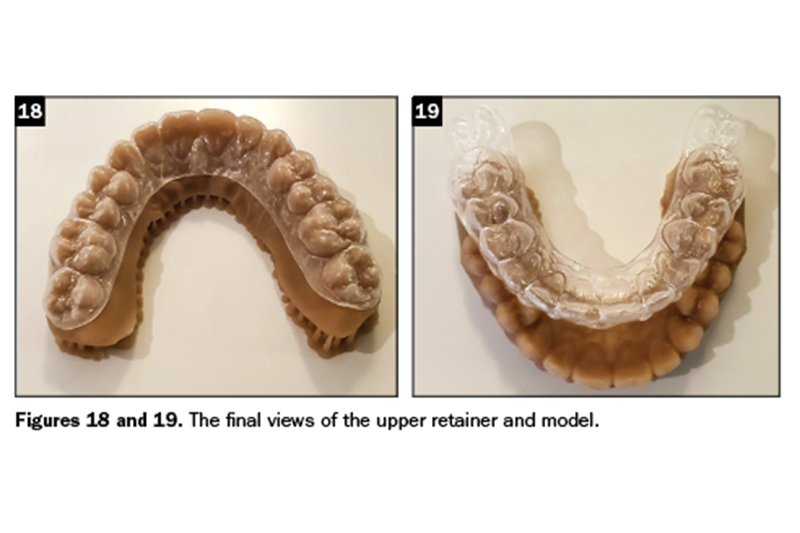

In our practice, 3D printing has numerous applications. The ability to print models for retainers, nightguards, diagnostic casts, and aligners is invaluable. In instances where retainers need to be delivered to the patient as soon as possible after the orthodontics or restorative procedure is completed, we can now take a highly accurate 3D scan. With the fast speed of the 3Demax, the staff can scan, print, and fabricate the retainers for the patient to pick up a few hours later and reduce the risk of orthodontic relapse.

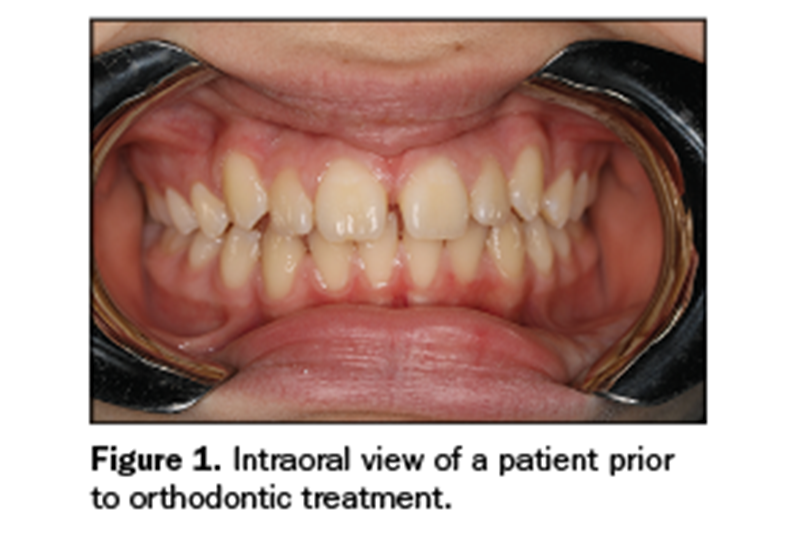

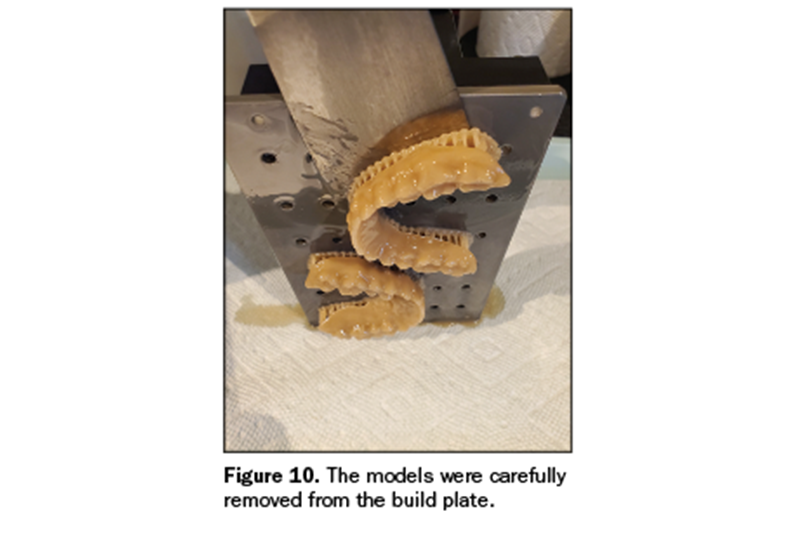

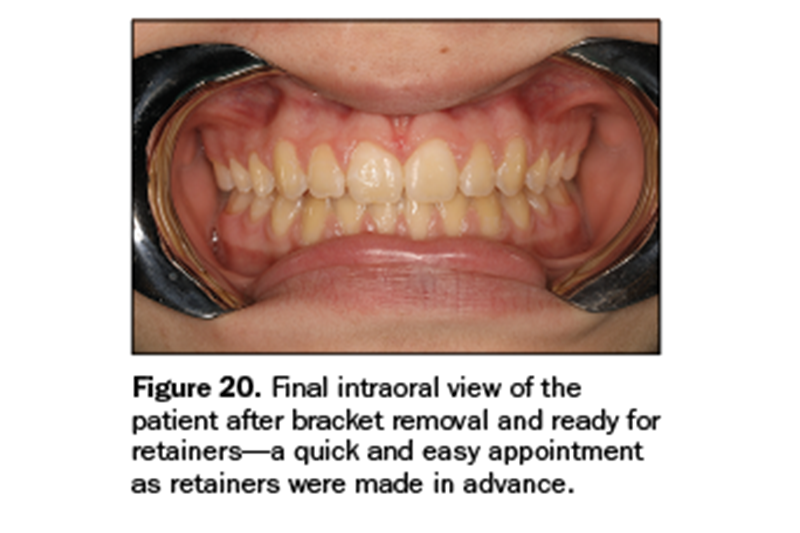

Figures 1 to 20 provide a case example of how we fabricate retainers ahead of time for patients with orthodontic brackets. It is simple to scan the patient, digitally remove the brackets, and fabricate the retainer so that it is ready to be inserted at the debonding appointment.

ABOUT THE AUTHOR

Dr. Latham received her undergraduate degree from Boston University and her DDS degree from the University of Michigan (U-M) School of Dentistry in 2011.

While attending the U-M School of Dentistry, Dr. Latham was the recipient of the William S. Kramer Award of Excellence, inducted into the Omicron Kappa Upsilon Dental Honor Society, and served as co-chair for the Scholars Program in Dental Leadership where she led a capstone project collaborating with students, faculty, and community dentists to increase the efficiency and efficacy of a local children’s clinic to help improve access to care.

Dr. Latham began her dental career as a general dentist for the US Navy serving in a military dental clinic in Rota, Spain, and returned to the United States to practice general dentistry with Tidewater Dental Group in Virginia Beach, Va. In 2014, she partnered with a successful multidisciplined practice, Brush and Floss Dental Center in Stratford, Conn, where she now maintains a private practice focused on orthodontic and restorative care. She can be reached at julialathamdds@gmail.com.

Disclosure: Dr. Latham reports no disclosures