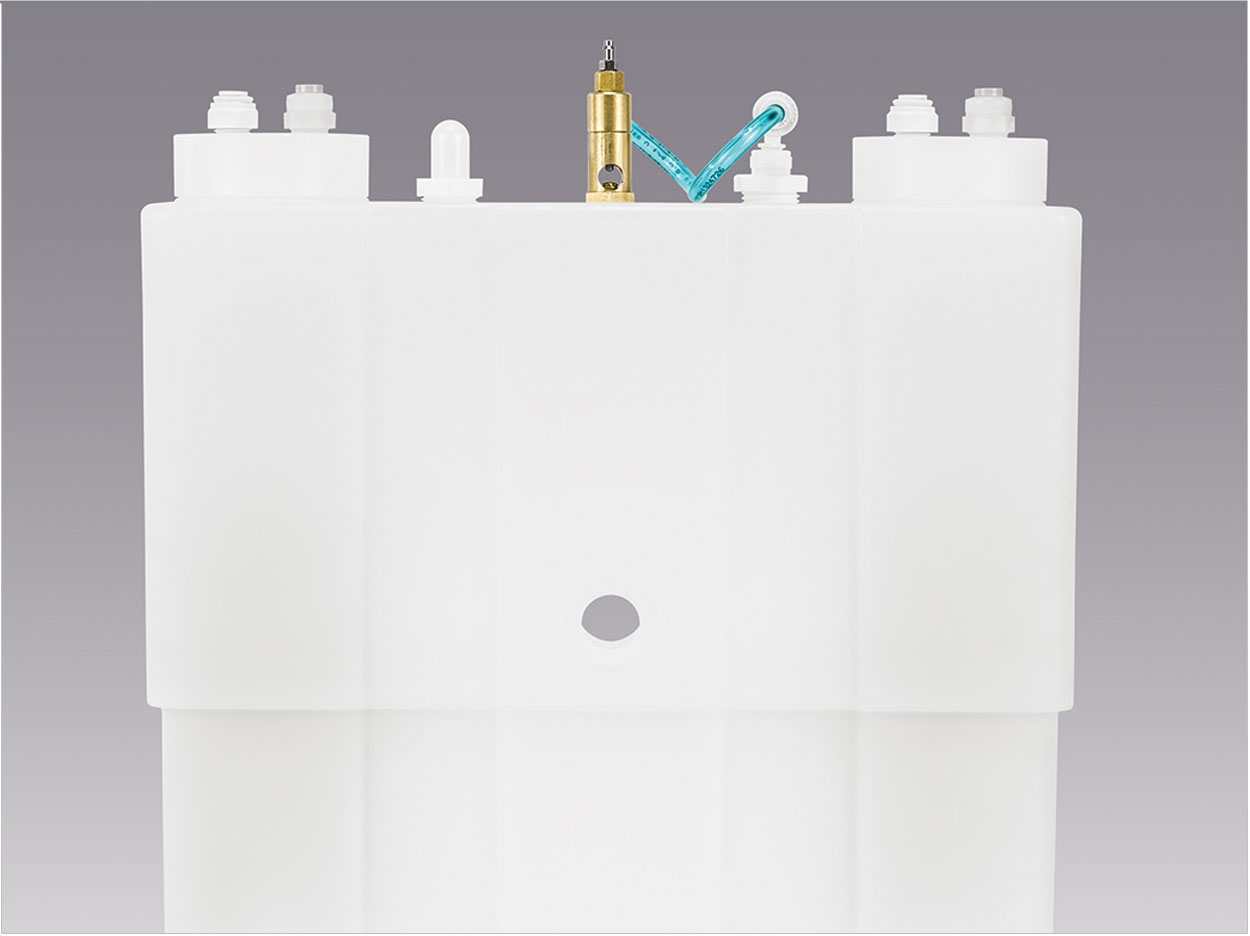

The VistaCool direct-to-drain system from Midmark Corp. reduces the temperature of sterilizer wastewater. Hot water, of course, can cause pipes to soften and deform. More importantly, cooler water reduces the potential of injury for staff that work with sterilizers.

“Wastewater will enter the VistaCool unit just below the sterilization cycle temperature. The most common cycles on the Midmark sterilizer run at 270°F, so the water entering the tank is just below that at approximately 265°F,” said Cathy Klein, instrument processing manager at Midmark.

“The wastewater runs through copper tubing that is in the tank. If the tank gets too hot, the VistaCool is connected to the cold water line so cold water will enter the tank to help cool it and the water before sending the water down the drain,” Ms. Klein said. “The water leaving the VistaCool will be approximately 170°F due to the temperature limits on the VistaCool thermal sensor.”

VistaCool also is designed to reduce sterilizer maintenance, guard drains, and prevent mold and mildew from collecting on cabinets caused by spills and exhaust from condensation systems. It reduces the number of used condensate bottles and tanks as well—and that means fewer spills with the potential for cross-contamination and big messes.

“Once the sterilizer is connected to the VistaCool, no portable condensate bottles or tanks are needed,” Ms. Klein said. “The VistaCool is a gravity-fed solution that, once it is set up and working properly, no manual intervention is needed.”

VistaCool is the only direct-to-drain system designed and tested to work with Midmark automatic sterilizers. The single unit is compatible with the Midmark M3 UltraFast Automatic Sterilizer. The double unit is designed for use with any two current Midmark sterilizers in combination, including the Midmark M3 sterilizer and the Midmark M9 and M11 UltraClave automatic sterilizers.

For more information, call (800) MIDMARK or go to midmark.com/vistacool.