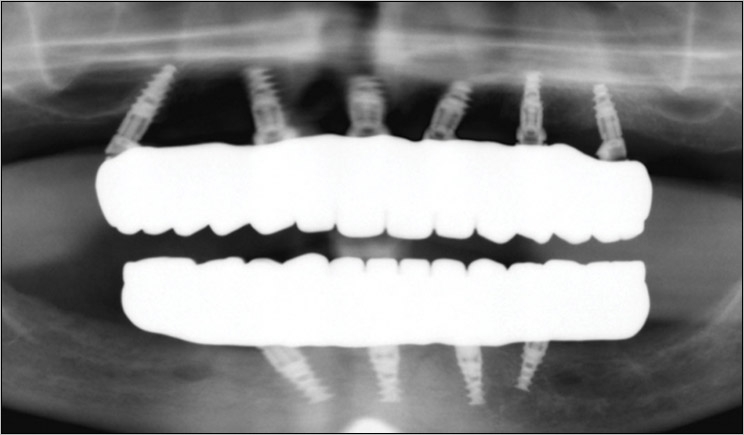

Today’s dental implants offer nearly universal success rates, though fractures do occur on very rare occasions. A team of Swedish researchers recently surveyed 2,670 patients to assess the prevalence of implant fractures and the factors that predispose these devices to greater risks.

According to the study, 44 implants out of 10,099 examined fractured for a failure rate of 0.44%. Half of these fractures happened between two and eight years after implementation. The researchers also found five factors that either increase or decrease the risk of fractures:

- The use of higher grades of titanium decreased the probability of fracture by 72.9%.

- Bruxism increased the probability of fracture by 1819.5%.

- Direct adjacency to cantilever increased the probability of fracture by 247.6%.

- Every 1-mm increase in implant length increased the probability of fracture by 22.3%.

- Every 1-mm increase in implant diameter decreased the probability of fracture by 96.9%.

Corresponding author Bruno Ramos Chrcanovic of the Department of Prosthodontics, Faculty of Odontology at Malmö University in Malmö, Sweden, shared his additional insights on his team’s study with Dentistry Today.

Q: The 0.44% failure rate seems very small. Did you expect such a low rate?

A: No. There are some few studies on the subject, with different follow-up periods, with different sample sizes (different amounts of patients and implants). For that reason, I could not predict any figure beforehand. It is important to note that the figures vary between implants of different diameters and different manufacturers.

Q: Were implants in some locations in the mouth subject to more fractures than others?

A: Generally speaking, the more posterior the implant is located, the higher the masticatory force, and consequently the higher the load on the implant-supported prosthesis. But it is not that simple. Other factors must also be taken into consideration, such as cantilever.

Q: What types of materials were used in the implant cases that you studied?

A: Commercially pure titanium (cpTi) of different grades, depending on the year of manufacture of the implants. This information is available in the text of the article.

Q: When did these implant surgeries take place, and how has implant technology changed since then?

A: The implants included in the study were placed between 1980 and 2014. In the 1980s and early 1990s, most implants were machined (or turned), and some had a surface treatment called TPS (titanium plasma sprayed). Most of them were also manufactured with cpTi-grade 1. Today there are implants with the so-called moderately rough surface, and they are manufactured with cpTi grade 3 or 4. However, the design has basically been the same.

Q: How can practitioners best account for the factors that lead to fractures during their implant procedures?

A: It depends on the probability of each factor. The presence of more than one factor in the same patient increases the risk, but it is not a simple sum of probabilities of different factors. It is more complex than that.

Q: Where can practitioners go for more information?

A: As mentioned before, there are some few studies on the subject, but none of them used regression models to try to identify risk factors that could be associated (here we are dealing with suggestion, assumption, allegation) with implant fracture, as my study did. My thesis (http://muep.mau.se/handle/2043/22587) also has a mini-chapter on the subject.

Related Articles

Study Uncovers Implant Failure Risk Factors

Antidepressants Increase the Risk of Implant Failure

Dental Implant Coating Halts Peri-Implantitis