A ceramic-based ink may allow surgeons to 3D-print bone parts complete with living cells that could be used to repair damaged bone tissue, according to the University of New South Wales (UNSW) Sydney.

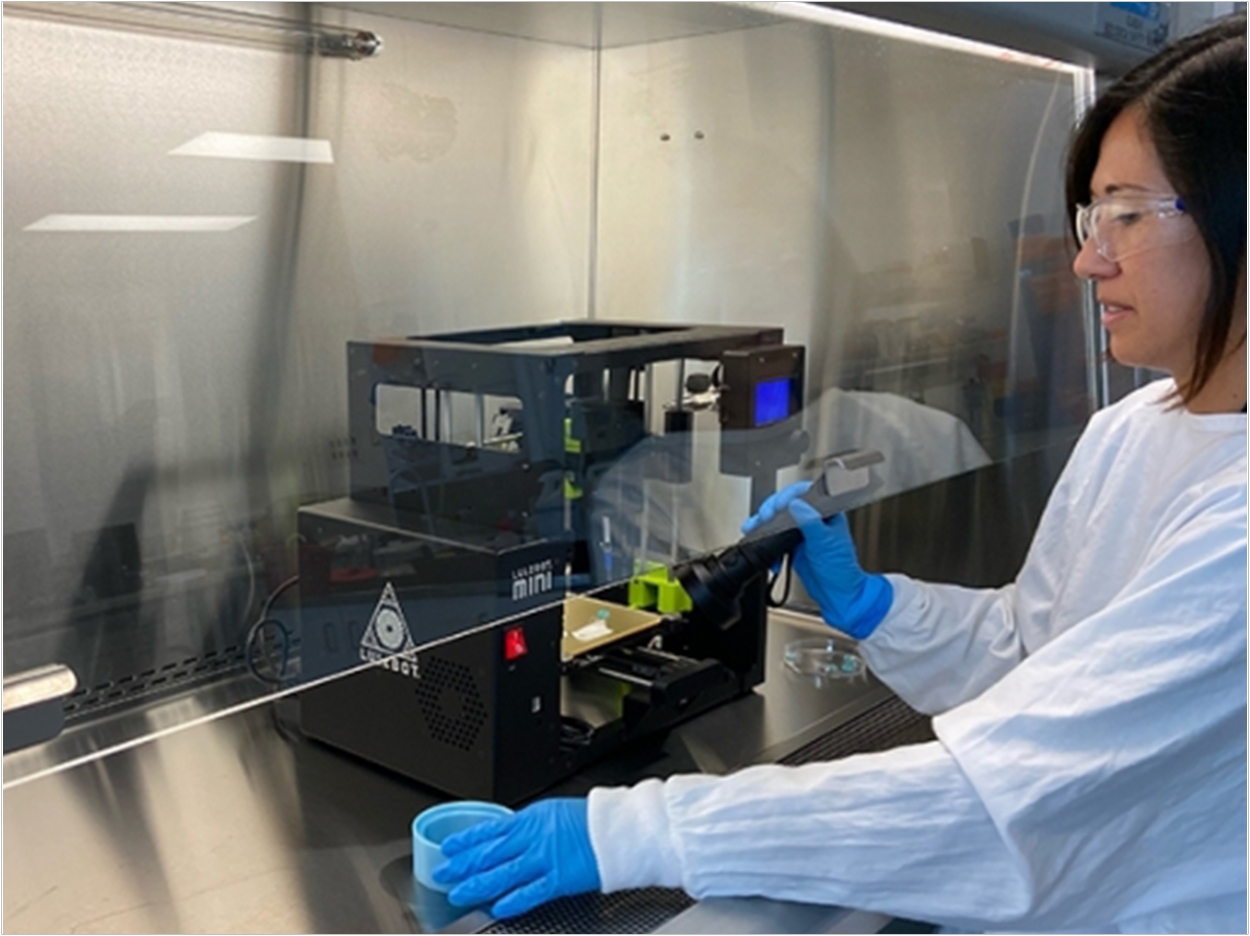

Using a 3D printer that deploys a special ink made up of calcium phosphate, researchers at the school have developed a technique known as ceramic omnidirectional bioprinting in cell suspensions (COBICS), enabling them to print bone-like structures that harden in a matter of minutes when placed in water.

While the idea of 3D printing bone-mimicking structures is not new, this is the first time such material can be created at room temperature complete with living cells and without harsh chemicals or radiation, said Dr. Iman Roohani of the UNSW School of Chemistry.

“This is a unique technology that can produce structures that closely mimic bone tissue,” Roohani said. “It could be used in clinical applications where there is a large demand for in situ repair of bone defects such as those caused by trauma, cancer, or where a big chunk of tissue is resected.”

Associate professor Kristopher Kilian, who co-developed the breakthrough technology with Roohani, said that the fact that living cells can be part of the 3D printed structure, together with its portability, make it a big advance on current state of the art technology.

Up until now, Kilian said, making a piece of bone-like material to repair bone tissue of a patient involves first going into a laboratory to fabricate the structures using high-temperature furnaces and toxic chemicals.

“This produces a dry material that is then brought into a clinical setting or in a laboratory, where they wash it profusely and then add living cells to it,” said Kilian.

“The cool thing about our technique is you can just extrude it directly into a place where there are cells, like a cavity in a patient’s bone. We can go directly into the bone where there are cells, blood vessels, and fat, and print a bone-like structure that already contains living cells, right in that area,” Kilian said.

“There are currently no technologies that can do that directly,” Kilian said.

“The ink takes advantage of a setting mechanism through the local nanocrystalization of its components in aqueous environments, converting the inorganic ink to mechanically interlocked bone apatite nanocrystals,” said Roohani.

“In other words, it forms a structure that is chemically similar to bone-building blocks. The ink is formulated in such a way that the conversion is quick, non-toxic in a biological environment, and it only initiates when ink is exposed to the body fluids, providing an ample working time for the end user, for example, surgeons,” said Roohani.

When the ink is combined with a collagenous substance containing living cells, it enables in situ fabrication of bone-like tissues, which may be suitable for bone tissue engineering applications, disease modeling, drug screening, and in situ reconstruction of bone and osteochondral defects, Roohani said.

Already, there has been keen interest from surgeons and medical technology manufacturers, according to the university. While it’s early days, Kilian said, this new bone-printing process could open up a whole new way of treating and repairing bone tissue.

“This advance really paves the way for numerous opportunities that we believe could prove transformation, from using the ink to create bone in the lab for disease modeling, as a bioactive material for dental restoration, to direct bone reconstruction in a patient,” Kilian said.

“I imagine a day where a patient needing a bone graft can walk into a clinic where the anatomical structure of their bone is imaged, translated to a 3D printer, and directly printed into the cavity with their own cells,” Kilian said.

“This has the potential to radically change current practice, reducing patient suffering and ultimately saving lives,” said Kilian.

Next, the researchers will perform in vivo tests in animal models to see if the living cells in the bone-like constructs continue to grow after being implanted in existing bone tissue.

The study, “Synthetic Bone-Like Structures Through Omnidirectional Ceramic Bioprinting in Cell Suspensions,” was published by Advanced Functional Materials.

Related Articles

Researchers Identify Genetic Disorder That Affects Craniofacial Skeleton

Biodegradable Gel May Improve Craniosynostosis Treatment

T Cells Lose Their Ability to Suppress Destruction During Periodontal Disease