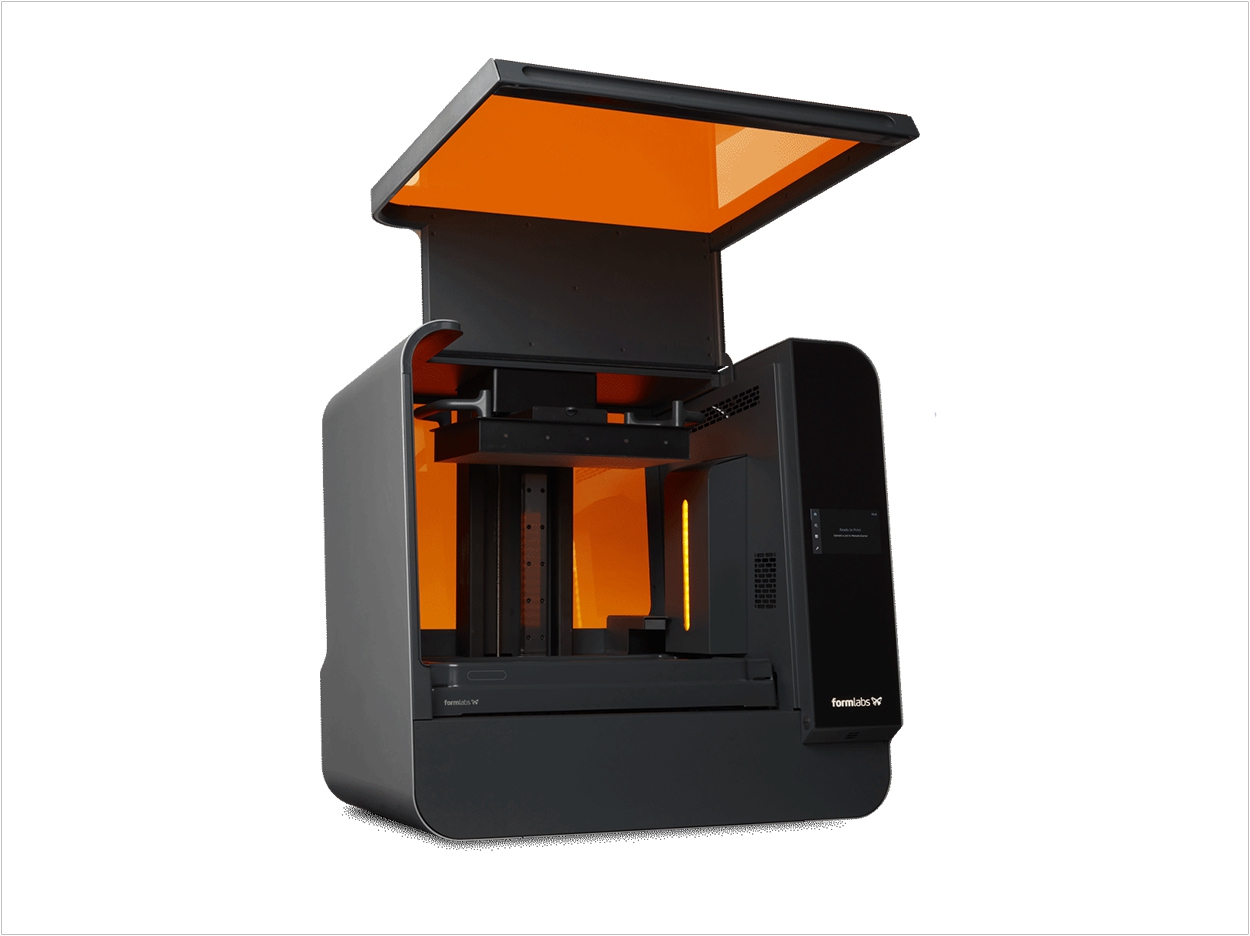

The Formlabs Form 3BL large format stereolithography (SLA) 3-D printer is optimized for biocompatible materials, according to the company. Formlabs also has announced that it will start shipping its Form 3L large format printer for accurate and repeatable prints across its larger build platform without compromising cost or quality. Both printers are designed to enable creators to print high-detail large-scale parts. Plus, Formlabs said, its Wash L + Cure L fully automated post-processing system for large-scale prints will ship in 2021.

With the Form 3L and Form 3BL, users can print large-scale parts or many smaller parts in a single build with stunning surface finish and detail that resemble final products, the company said. They also provide a build volume of 33.5 by 20 by 30 cm (13.2 by 7.9 by 11.8 in), which is five times larger than the Formlabs Form 3 desktop SLA 3-D printer. They feature an intuitive workflow with automatic resin dispensing, simple print preparation software, and an easy to use interface as well, Formlabs said.

The robust end-to-end system is designed for nonstop throughput with minimal intervention. Access to nearly all of Formlabs’ materials library, ensuring a stable supply chain and access to the resins needed for any project, includes biocompatible materials. The Form 3BL specifically balances throughput, quality, and reliability and has been validated by Formlabs’ dental team to meet the accuracy requirements for dental aligner production with consistent part quality and accuracy across the entire build plane, according to the company. Additionally, with the Form 3BL, users can meet tight deliverable windows needed to produce customized surgical guides, Formlabs said.

The Form 3L is available and shipping now. The Form 3BL is available for pre-order and will ship in October 2020.

Related Articles

Resins Expand Library of Materials for 3-D Printing Dental Devices

Dental School Taps 3-D Printing to Create COVID-19 Testing Swabs