A hybrid implant coating made from antibacterial silver and an antibiotic will protect patients from infection in the future, report researchers at the Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM), with the antibiotic tailored to each patient’s unique requirements for even better protection.

The AntiSelectInfekt project came about in collaboration with a research team from Chairté-Universtitätsmedizin Berlin. Focused on artificial knee, shoulder, and hip joints, the researchers said they are planning a technology transfer to dental implants as well, though further adaptation is required due to the different microbial environment in the mouth.

On average, 1% to 2% of knee, shoulder, or hip implant patients will develop an infection following the operation. If the level of discomfort is so severe that another surgery is necessary, an infection can be expected in up to 4% of all cases, the researchers said. Even if the individual risk is low, infection can affect many patients due to the growing frequency of the surgery.

When antibiotics don’t help, infections can be long and painful, the researchers said. In worst-case scenarios, implants need to be replaced, requiring additional surgery. But the new process promises to significantly reduce the risk of infection as a hybrid coating of antibacterial silver and an antibiotic tailored to the patient’s requirements is applied to the implant.

“Surface treatment is one of the areas our institute specializes in. Applying this expertise to medicine was a natural choice,” said Kai Borcherding, head of medical technology and life sciences at Fraunhofer IFAM, which began developing the idea four years ago.

Fraunhofer researchers further developed, tested, and implemented the concept through the AntiSelectInfekt project in collaboration with the Julius Wolff Institute and the BIH Center for Regenerative Therapies of Chairté in Berlin with results they called promising.

“The preclinical studies have demonstrated that the hybrid implant coating effectively reduces the rate of infection,” said Britt Wildemann, who is in charge of the studies on effectiveness and biocompatibility in Berlin and is now head of experimental trauma surgery at Jena University Hospital.

Implant coatings are not new, the researchers said, and the ability of silver and antibiotics to combat infections associated with implants has long been studied. But this approach combines the two and vastly improves active protection against bacterial, the researchers said, in addition to other benefits, as the antibiotic can be tailored to each patient’s requirements.

The special coating technology developed by Fraunhofer IFAM also regulates the release of the antimicrobial substances. While the antibiotic is released in full once the implant is in place, the silver particles take effect gradually close to the surface over a longer period of time, providing lasting protection that continues into the healing phase.

The coating process is based on tried and true technologies further developed specifically for the project, the researchers said.

“The first step is to apply a structure to the surface of the titanium implant using a laser. This creates a porous layer,” said Borcherding.

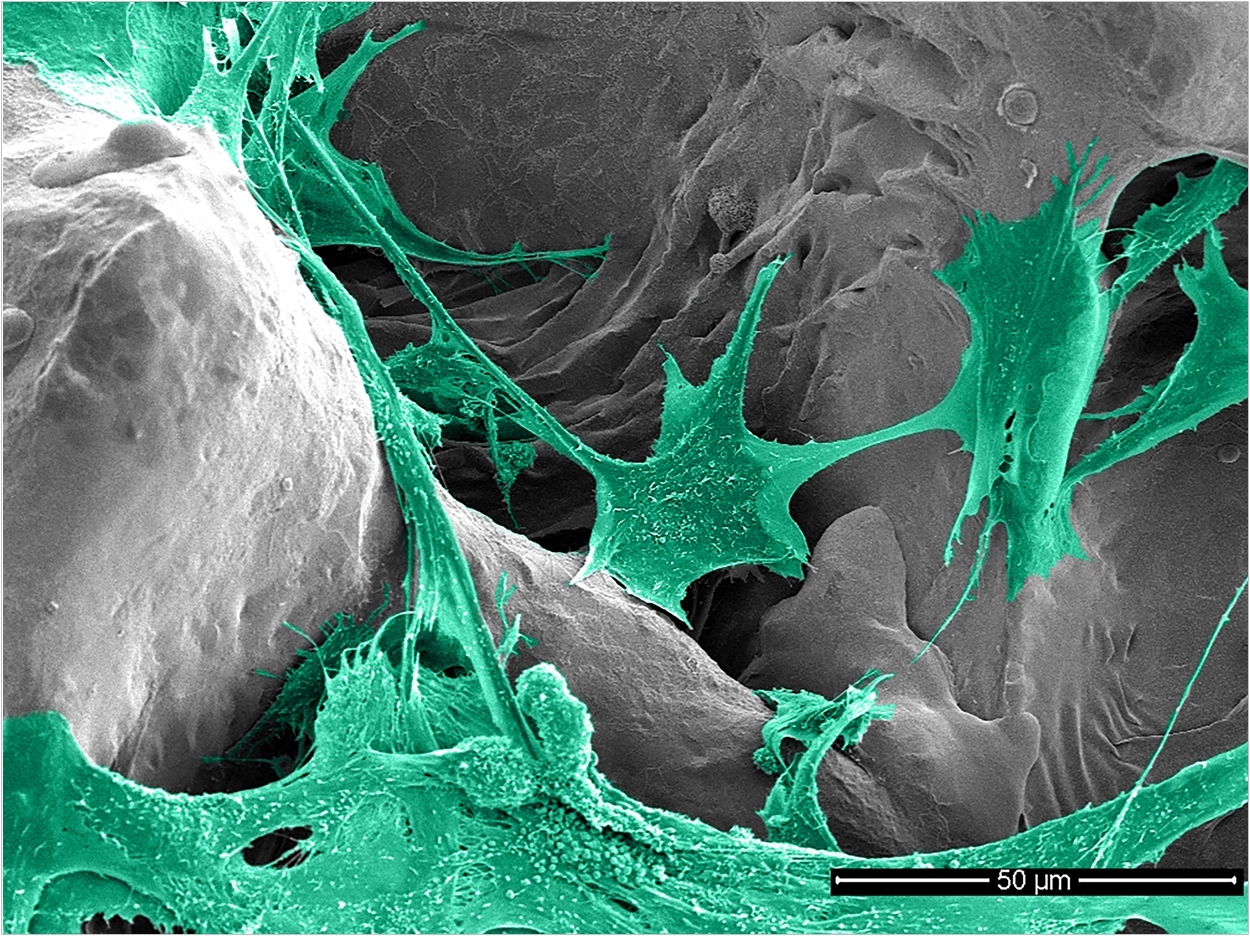

Tiny pores that are mere micrometers in size and invisible to the naked eye appear on the titanium surface. These pores are amphora-shaped, meaning they are narrower above and wider below. In the second step, researchers use the process of physical vapor disposition to apply a layer containing silver particles.

These amphora-shaped pores can be filled during the surgery. Just before implantation, the surgeon immerses the sterile implant with silver coating in a solution containing the antibiotic.

“We have seen in preclinical studies that the entire process is very simple and only takes a few minutes,” said Wildemann.

Once the implant has been implanted, the antibiotic begins releasing into the surrounding tissue, killing off any bacteria that could cause an infection. The effect of the silver coating is delayed and lasts much longer. The silver ions remain active for several weeks and offer protection from infection during the healing phase.

The success would not have been possible without numerous experiments along the way, the researchers said. Biocompatibility and osseointegration were studied both in lab tests with human bone cells and in the animal model.

“One of the challenges during the development phase was ensuring the concentration of antibiotic was high enough to kill bacteria, but not so high that it would damage the growing bone cells,” said Borcherding.

Also, the pores applied to the titanium surface with the laser treatment ensure better bone adherence.

“Our study has shown that surface modification increases bone contact: 89% contact with implants featuring the hybrid coating, compared to just 52% bone contact in the control group,” said Wildemann. “We were also able to prove that cells grow into the amphora-shaped pores and thus anchor the implant much more effectively.”

The project already has met with great interest among implant manufacturers and providers of coating services, the researchers said, particularly because no new implants need to be developed for the process. Products that already are available can be coated. Discussions with manufacturers are being intensified in the project’s final stages to ensure the technology can be used for patients in the near future, the researchers said.

Related Articles

Implant Coating May Suppress Inflammatory Responses

Nano-Coating Inactivates 100% of Bacteria on Implants

Dental Implant Coating Halts Peri-Implantitis