Deal or no deal? This is the question any dentist would ask when deciding whether to purchase the latest 3-dimensional digital technology, considering the price. However, price should not prevent the latest digital technology from being integrated into our practices in the form of inLab CEREC (Sirona) fabrication. Alexander Pope once said, “Be not the first by whom the new are tried, nor yet the last to lay the old aside.”

STRENGTH

Most importantly, the choices of materials that can be used with inLab have greater strength than those that can be used chairside. Yttrium-stabilized zirconium oxide (Yz) for high-strength (900 to 1,100 MPa) copings and frameworks is available from 3M ESPE (Lava), Sirona (inCoris ZI), and Vident (inVizion), to mention but a few options. These Yz materials cannot be used to fabricate restorations at chairside. InVizion, with 1,000 MPa of flexural strength, is 4 times as strong and is more durable than other materials used at chairside. In comparison, 2 popular in-office materials have 140 to 200 MPa of flexural strength. However, inVizion also requires a 7-hour cycle, which takes more time and costs more in lab fees than in-office materials.

Using Vident products as an example, other high-strength materials that can be used with inLab CEREC include In-Ceram Spinell (very translucent at 350 MPa); In-Ceram Alumina (good all around, time tested) at 500 MPa; or In-Ceram Zirconia with high strength of 750 MPa. All of these materials are built with VM7 porcelain for the lowest wear on opposing dentition and wear better than any chairside porcelains on the market. A finished inVizion crown with VM9 porcelain is much stronger than a porcelain-fused-to-metal crown.

|

|

|

Figure 1. Preoperative buccal view. |

Figure 2. Preoperative occlusal view. |

|

|

|

Figure 3. Crown removal begins using a fissure bur on the buccal surface. |

Figure 4. Completed crown removal. |

|

|

|

Figure 5. Photo-cure of core buildup. |

Figure 6. Placement of CompCore AF SyringeMix material for final core. |

|

|

|

Figure 7. Completed core. |

Figure 8. Retraction using Expasyl. |

AESTHETICS AND CUSTOMIZATION

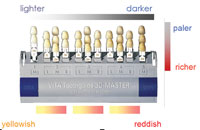

Crowns made with the inLab CEREC system can be made more aesthetically pleasing than chairside alternatives. The ceramist can easily customize the in-Lab porcelain crowns with layering techniques using incisal chroma and opalescent powders, for example.

ACCURACY AND FIT

The impressions and resulting inLab restorations provide for extreme accuracy and great marginal integrity.

CHAIRSIDE EFFICIENCY

Since adjustments can be made more easily on the model than in the mouth, any discrepancies can be corrected before insertion, saving chair time.

VERSATILITY OF PROCEDURES

The new inLab CEREC MC XL (Sirona) is twice as fast and more accurate than previous models. InLab CEREC MC XL with Yz porcelain materials can be used for making cantilevered pontics, veneers, inlay bridges, Maryland bridges, and bridges in a larger milling chamber that can accommodate bridges in excess of 40 mm. Because the sintering procedure necessary for Yz cannot be performed efficiently in the office, the inLab approach provides practitioners with more choices for copings and frameworks.

NO METAL COLLARS, IMPROVED DIAGNOSTICS

Crowns fabricated without metal collars are radiographically translucent, making it easier to detect decay beneath the crown instead of seeing a “big white blob” on the radiograph.

|

|

|

Figures 9 and 10. T-LOC Triple Tray tried in the mouth in closed position. |

|

|

|

|

|

| Figures 11 to 15. Triple Tray impression procedure. Pentamix 2 used to load syringe material and Triple Tray with heavier body material. Syringe material blown into sulcus, followed by seating of Triple Tray. |

AN EXPANDED ARSENAL FOR DENTIST AND TECHNICIAN

To perform the inLab technique, the model is poured in scannable stone followed by the use of the optical scanner. The design process begins, and the porcelain is then milled to specifications. The next step is either to infiltrate or sinter, which provides more strength than using a chairside technique. The ceramist can now build porcelain, contour, stain and glaze, and return to the clinician a much stronger, more aesthetic, better-fitting and less chair time-consuming restoration. Clearly, the finished restoration using the inLab CEREC technique would be best for the patient in terms of longevity, appearance, and fit.

|

|

|

|

Figures 16 to 18. The impression was sent to the laboratory, where the CEREC system created dies and fabricated proper porcelain fit, form, and color. |

|

|

|

Figure 19. Completed crown. |

Figure 20. Completed crown delivered to patient. |

CASE REPORT

A 72-year-old female patient required the replacement of a crown on tooth No. 5, which had previous endodontic treatment. Figures 1 and 2 depict the buccal and occlusal views, showing recession in the darkened root and the stained, worn facing made of acrylic.

Crown removal was begun using a fissure bur on the buccal (Figure 3), and the completed crown re-moval is shown in Figure 4. Bonding for the core build-up using iBond (Heraeus Kulzer) is shown being photo-cured in Figure 5. Placement of the CompCore AF SyringeMix material (Premier) for the final core is shown in Figure 6, and the completed core can be seen in Figure 7. Retraction is being accomplished as Expasyl (Kerr) is being syringed to place in Figure 8. The T-LOC Triple Tray is tried in the mouth in closed position showing proper seating in Figures 9 and 10. A Pentamix 2 automatic mixer (3M ESPE) was used to load the syringe material and load the Triple Tray with the heavier body material. The patient then received the syringe material that was then blown into the sulcus for better adaptation, followed by the seating of the Triple Tray with the heavier body material as shown in Figures 11 to 15.

The impression was sent to the laboratory, where the CEREC system was used to create the dies from the Triple Tray and fabricate the proper porcelain fit, form, and color (Figures 16 to 18). The completed crown as seen in Figure 19 was now ready for delivery to the patient (Figure 20).

Acknowledgment

Photos courtesy of S. Rand Werrin, DDS.

Dr. Goldstein has maintained a private practice in Beachwood, Ohio, for 31 years, focused on cosmetic and implant dentistry. He is a Fellow of the AGD and is currently pursuing his accreditation in the American Academy of Cosmetic Dentistry. He has held teaching appointments at Case Western Reserve School of Dental Medicine and as an attending in the Cleveland Metropolitan General Hospital GPR program. He earned his DDS degree from Case Western Reserve University in 1975 and can be reached at (216) 464-1700 or drjhgdds@aol.com.

Dr. Werrin co-operates a private cosmetic and restorative dental practice in Pittsburgh, Pa, with Dr. Charles J. Miller, his partner of 38 years, and Dr. John W. Gruendel, his partner of 27 years. He is the inventor of and holds patents on 8 Premier Triple Tray designs. As the associate professor for the Department of Continuing Education and Medicine at the School of Dental Medicine of the Univer-sity of Pittsburgh, Dr. Werrin has lectured worldwide and co-authored numerous articles on the subject of restorative dentistry. He earned his DDS degree in 1967 from Temple University and served 2 years after graduation as a general dentist in the US Air Force. He can be reached at (412) 621-0200 or werrin@dentalpgh.com.