One of the most critical components of implant dentistry is the radiographic image. While managing the variables that can affect the quality and consistency of x-ray images over time is an important element in all dental practices, it is particularly important for successful planning, monitoring changes in hard-tissue regeneration, and completing dental implant procedures.

VARIABLES FOR FILM RADIOGRAPHS

Film radiographs have a large number of variables to manage. If not executed properly, any one of these variables can affect the x-ray images and thus lead to negative consequences for the treatment process and, in some cases, for the quality of patient care. Several of the variables are controllable by the implant dentist; however, a few of them are beyond our control. An understanding of these variables and of the procedures needed to maintain image consistency and quality will help to improve the ability to provide uniformly high-quality care.

Among the variables that are nominally under the control of the dentist using film radiographs are those associated with the film-processing equipment, including things such as temperature and chemical concentration. Image distortion creating difficulty in using manual overlays is another variable that is nominally under the dentists control.

The ideal way to maintain the quality of film processor chemicals is to monitor the number of films that have been developed using a given batch rather than the amount of time chemicals have been in the developer. In cases where only a few films have been processed during the course of a day, it is unnecessary to change developer. However, automatic developers are programmed to replenish chemicals at time-based and not usage-based intervals. This means that on days where many films are processed, developer quality will deteriorate due to usage. By the end of a busy day, x-ray quality may be significantly affected. In addition, exposure to air causes chemical deterioration, regardless of usage. The result is that even though this variable is managed automatically and is technically under the dentists control, actually keeping it within certain limits can be difficult. In cases where deterioration of image quality is noticed during the workday, an interruption in the normal flow of film processing must occur to replenish chemicals, which contributes to increasing overhead costs.

Temperature is another such variable. Of course, processing equipment is equipped with thermostatically controlled temperature maintenance. Water temperature is automatically maintained at the desired temperature for proper processing. However, while these units are equipped with heating elements, it may be the case that, under certain circumstances, the water temperature may rise above the desired temperature. In this case, the processor is not equipped to lower the temperature.

The orientation of the radiographic image and the associated development of an implant design overlay also contribute to the variables that must be managed when film-based x-rays are used. Even when head position is ideal at the time a panoramic x-ray is taken, image distortion can be significant, often approaching 20%.1 And when slight variations in head positioning are taken into account, the distortion factor can be even greater.2 This can mean that the creation of a manual design overlay is based on an approximation of the patients jaw and tooth structure, rather than on an image that is highly representative.

Other variables associated with film radiography are not so directly under the dentist’s control; or when they are, they result in additional expense to implement. These include water quality, shelf life of chemicals, shipping and storage conditions for chemicals, storage of unexposed film, and deterioration over time of x-ray images.

Water quality varies by region of the country, location within a region, municipal water management, and delivery systems within the office or office building. The chemicals added to a water supply to ensure drinking quality vary widely among municipalities, as do the amount of minerals naturally occurring in the source water as well as substances, such as fluorides, which are added to some water. Within a building, the age and composition of water pipes can also contribute to contaminant levels. Water filtering systems are often necessary to ensure consistent water quality, but even these need regular routine maintenance. When they are not properly maintained, the result can be water that compromises the quality of film processing.

Chemical packaging always shows an expiration date, but how many dentists pay strict attention to this variable? In order to get price breaks, many dentists order fairly large quantities of chemicals and sometimes keep them beyond recommended expiration dates. In addition, the quality of chemicals depends on such variables as the conditions under which they were shipped and stored. Exposure to wide temperature variations, including extremes of heat and cold, certainly go beyond the recommended storage conditions for most chemicals and can compromise quality and freshness.

Storage conditions for unexposed film in warehouses also represent a variable that can affect outcomes. Do the (often) tens of thousands of packages of film many distributors keep on hand remain refrigerated, or at least in conditions of optimal temperature control? Again, the answer to this question is unknown, although variations in film storage conditions can significantly impact image quality. In addition, potential accidental light contamination of a batch of stored film is also a variable that needs to be considered, although its effect won’t be known until it is time for the film to be used.

Finally, the image quality of the exposed x-ray film itself can deteriorate fairly rapidly under typical storage conditions, eg, in filing cabinets. When a comparison is needed between x-rays taken at different points over a long time period, the problem often becomes compounded because an older (and thus possibly compromised) image is being compared with a newer one.

THE ADVANTAGES OF DIGITAL RADIOGRAPHY

|

|

|

Figures 1 and 2. Set of 2 film x-rays demonstrating difficulty in maintaining consistency and clarity of image used to monitor calcium uptake over time. |

|

|

|

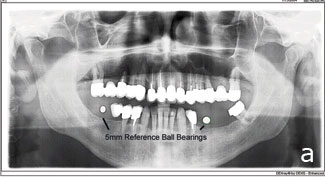

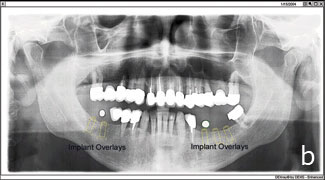

Figures 3a and 3b. Panoramic radiograph with radiographic ball bearings visible. |

|

|

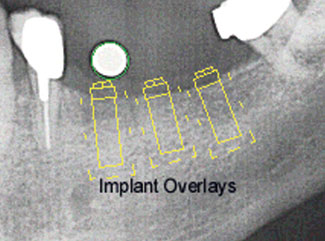

Figure 4. Computer-generated radiograph with implant overlays visible and called out. |

Digital radiography systems provide the most effective way to manage x-ray variables in the dental office. Obviously, since film is not involved in the digital radiography process, variables associated with water quality, temperature, film storage and exposure, chemicals, and processing equipment no longer need to be considered. But these aren’t the only variables to be considered. Digital radiography also positively impacts variables associated with image distortion, the creation of overlays, and image quality deterioration associated with the storage of x-rays.

Digital radiography is of particular interest to dentists specializing in implants. Several dental implant procedures exist for which eliminating variables provides important benefits. These procedures include the ability to monitor the maturity of hard-tissue regeneration from the preoperative state, monitoring tissue production, often over a period of months, and assessing the success of the implant itself. These procedures also include obtaining consistent image orientation and a reduction through the use of digital rather than manual overlays in the margin of error previously tolerated in creating an overlay. The need to have consistent image quality over time for comparison purposes is another area in which digital radiography offers important advances compared to film.

Film-based x-rays taken to monitor radiopacity indicating calcium uptake that represents new hard-tissue growth are frequently unreliable because of the impact of variables affecting their consistency (Figures 1 and 2).

A digital radiograph, on the other hand, because it eliminates the variables associated with film, provides a radiograph whose quality is constant over time.

Where eliminating distortion associated with panoramic x-rays used in implant dentistry is concerned, one manufacturer, DEXIS, has introduced an auto-callibration feature to correct for image distortion. In the DEXimplant module of its digital radiography software, DEXIS provides for the use of 5-mm ball bearings as references when the radiograph is taken. The DEXimplant process begins with a panoramic digital x-ray, and these radiographic ball bearings are used for reference as the image is captured. As the image is manipulated and enhanced during the design process, the ball bearings provide reference points, and the computer software uses them to automatically correct for the distortion that is problematic in manual implant design (Figures 3a and 3b).

DEXimplant also contains an extensive library of images of all popular dental implants categorized by manufacturer and size. Once the panoramic x-ray has been captured and displayed, these implant images can be placed on the panoramic image. DEXimplant then automatically adjusts the implant overlay in 2 dimensions to compensate for distortion. The software enables the dentist to gain a more accurate picture of the proposed treatment than otherwise would be possible (Figure 4).

DEXimplant software works with images captured from any panoramic x-ray system, and includes a second module, DEXbone, that enables dentists to monitor the success of the implant. These 2 modules are also important tools for communicating the design and progress of dental implants to patients.

Finally, digital radiography completely eliminates variables associated with the conditions under which images are stored. The implant dentist has images for comparison that have been stored under exactly the same conditions and represent exactly the image captured at the time it was taken. There are no storage variables to be considered with digital radiography.

CONCLUSION

The implications of virtually eliminating the variables associated with film x-rays in implant dentistry are profound. Where distorted and compromised images are the basis of designing treatment, there is an associated increase in risk for the patient as well as for the dentist. Thus, risk management becomes an important component of using the best available technology in the diagnosis, design, and installation of implants. Where small mistakes can result in serious health consequences, it is important to take every measure to ensure that the patients well-being is not compromised by the use of technology that is subject to variables that no longer need to be part of the process.

References

1. Scarfe WC, Eraso FE, Farman AG. Characteristics of the Orthopantomo-graph OP 100. Dentomaxillofac Radiol. 1998;27:51-57.

2. McKee IW, Glover KE, Williamson PC, et al. The effect of vertical and horizontal head positioning in panoramic radiography on mesiodistal tooth angulations. Angle Orthod. 2001;71:442-451.

Dr. Callan is a periodontist in Little Rock, Ark. His focus is on dental implants and hard- and soft-tissue regeneration for conventional and implant dentistry. He has written numerous articles on these subjects and provides over-the-shoulder, live surgical training to clinicians. He can be reached at (501) 224-1122, dcallan@doncallan.com, or by visiting doncallan.com.