Most implant abutments and related components require parallelism within approximately 10° to function properly. Implant-angulation problems result from a non-parallel implant placement and in flared maxillary bone situations. This may preclude the use of a conventional implant abutment and corresponding attachment.

When individual implants are not aligned or placed in the premaxilla, custom abutments may be used to correct for implant angulation variations, and the final implant restorations end up as cement-retained restorations. Our optimal restorative objective is to design screw-retained restorations, especially in complete-arch restorations. To avoid labial, buccal, or incisal screw access openings, and to eliminate the risks associated with the excess cement left behind, angle-correcting abutments can be used, such as the Dynamic TiBase Angulated Screw Channel (Dynamic Abutment Solutions from Preat). This type of abutment can correct misaligned implants up to 30° in a 360° radius and render the restoration a screw-retained type.

Consider the increased use of monolithic zirconia in complete-mouth rehabilitations. The following case presents how to fabricate a zirconia complete arch prosthesis for a maxillary terminal dentition using the Dynamic TiBase Angulated Screw Channel.

|

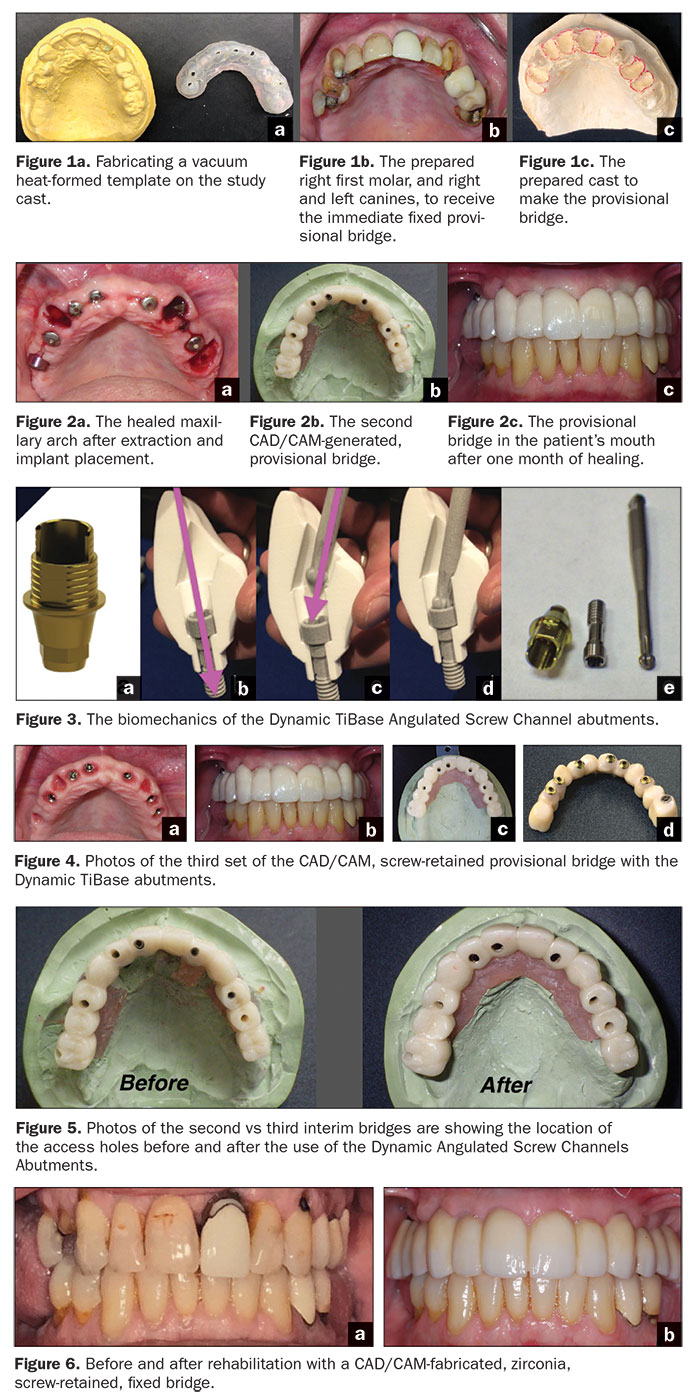

Step 1: Remove all maxillary teeth, except the right and left canines and the left first molar. Then, immediately place 7 dental implants in the extraction sockets with their healing abutments and place a cemented interim fixed bridge while keeping in mind the need to reline all pontics to conform to the healing ridge and the gingival contour of the extraction sockets.

Step 2: After one month of healing, an open tray impression of the implants is made and sent to the laboratory to make a screw-retained, interim-fixed implant bridge after the cast-removal of both canines and the first molar.

Step 3: Place the screw-retained, interim-fixed implant bridge and surgically remove of the canines and the first molar. This first provisional prosthesis is needed for healing purposes, evaluating aesthetics and occlusion, evaluating the position of the screw openings, and eventually ordering Dynamic TiBase abutments corresponding to the type of implants present.

Step 4: After 2 months of healing, make a new, open tray impression to fabricate a CAD/CAM PMMA, screw-retained provisional bridge with ovate pontics and adequate gingival embrasures around the implants. This CAD/CAM PMMA prosthesis will represent the blueprint of the final zirconia prosthesis. Dynamic TiBase Angulated Screw Abutments were used for any correction of implant angulation in this case. Experience suggests that if a few of these abutments are used, it is practical to use Dynamic TiBase on all the abutments.

Step 5: After one month of tissue and occlusal adjustment and patient adaptation to the CAD/CAM provisional bridge, a copy of this bridge is sent to the lab to finalize the final CAD/CAM zirconia fixed bridge. Once the zirconia bridge is finished, each Dynamic TiBase abutment will be cemented into each respective opening with a resin-type cement.

Step 6: Place and adjust the final zirconia bridge. Oral hygiene and prosthetic instructions are given to the patient, and continuous care scheduled.

For more information, call Preat at (800) 232-7732 or visit preat.com.

Dr. Daher is a graduate of the University of California, Los Angeles and the University of Southern California. He is a board-certified prosthodontist, a Fellow in the American College of Prosthodontists, and a Fellow in the International College of Dentists. He is the co-director of the Global Dental Implant Academy. He is a former associate professor and a past director of the advanced prosthodontics program at Loma Linda University. He maintains a private practice in LaVerne, Calif. He can be reached at tonydaher@verizon.net.